Keith’s work on Cu-base metal-intermetallic nanocomposites is published in Nature Scientific Reports [web, pdf]!

This work includes collaboration efforts with Dr. Aindow and Dr. Dongare’s groups. More importantly, three UConn undergraduate students (Leopolod Valencia Jr., Jack Morley, and Thomas Bissell) made a great contribution to this work!

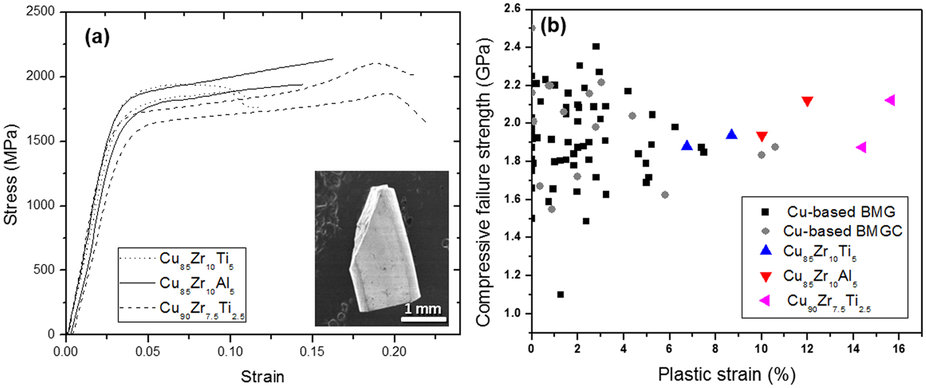

Abstract: Bulk metallic glasses (BMGs) and nanocrystalline metals (NMs) have been extensively investigated due to their superior strengths and elastic limits. Despite these excellent mechanical properties, low ductility at room temperature and poor microstructural stability at elevated temperatures often limit their practical applications. Thus, there is a need for a metallic material system that can overcome these performance limits of BMGs and NMs. Here, we present novel Cu-based metal-intermetallic nanostructured composites (MINCs), which exhibit high ultimate compressive strengths (over 2 GPa), high compressive failure strain (over 20%), and superior microstructural stability even at temperatures above the glass transition temperature of Cu-based BMGs. Rapid solidification produces a unique ultra-fine microstructure that contains a large volume fraction of Cu5Zr superlattice intermetallic compound; this contributes to the high strength and superior thermal stability. Mechanical and microstructural characterizations reveal that substantial accumulation of phase boundary sliding at metal/intermetallic interfaces accounts for the extensive ductility observed.

(a) Engineering stress-strain curves of Cu-based MINCs in this study. The inset is the scanning electron microscope image of fractured Cu85Zr10Ti5 specimen. (b) Plot of plastic strain vs. fracture strength of Cu-based bulk metallic glasses, Cu-based bulk metallic glass composites, and Cu-based MINCs in this study. Note that we obtained data from Cu alloys that contains Cu as the major composition component.