(Sponsor: UConn)

Despite the excellent ductility that is characteristic of pure metals, their application as a structural material has been limited due to their poor specific strength. Therefore, strengthening methods such as solid solution strengthening, precipitation strengthening, and grain size reduction strengthening have been used in an attempt to improve the specific strength of metals. Especially, the reduction of grain size to the nanometer scale has been extensively used to produce ultra-high strength metals, which have been termed nanocrystalline (NC) metals. Also, as an extreme case of grain size reduction, an alloy with a specially chosen composition can be amorphized, resulting in a bulk metallic glass (BMG), which has proven to be one of the strongest metallic systems. Although successful in increasing the strength of a metallic system, these strengthening processes usually bring out brittleness because conventional plastic deformation mechanisms, for instance, dislocation plasticity, are not effectively operative or not available. Without plasticity mechanisms, a material loses the capability to relieve the stress localized at a stress concentrator, such as a surface flaw or micro-crack. This high stress concentration leads to the catastrophic brittle failure. Co-based BMGs (5 GPa of ultra-high yield strength) have been shown to have strengths even higher than ceramic alumina (2.5 GPa of yield strength), but exhibit almost no plasticity at room temperature. Most NC metals also exhibit poor ductility at room temperature because dense grain boundaries do not allow dislocations to travel across the material volume. Only in some cases, such as the introduction of nano-twin boundaries or abnormally large grains, NC metals are able to exhibit enhanced ductility.

More challenging issue present for both BMGs and NC metals is the improvement of their high temperature stability. The glass transition of BMGs allows for various plastic forming methods to be available at relatively low temperatures. However, this ease in formability implies poor high temperature mechanical properties since it is certain that the BMG will become viscous and mechanically unstable at and above a glass transition temperature. A similar challenge is present at high temperatures for NC metals because of the energetic favorability for grain growth to occur, providing difficulty in maintaining ultra-fine grain size. Although making a composite with a ductile second phase or large grain would overcome brittleness issues, which were discussed previously, the structural stability at elevated temperatures would be still poor provided that the matrix material is BMG or NC metal. Therefore, it is these challenges, which confirm the importance of identifying a new material system that possesses not only enhanced strength and ductility but also superior structural stability at elevated temperatures.

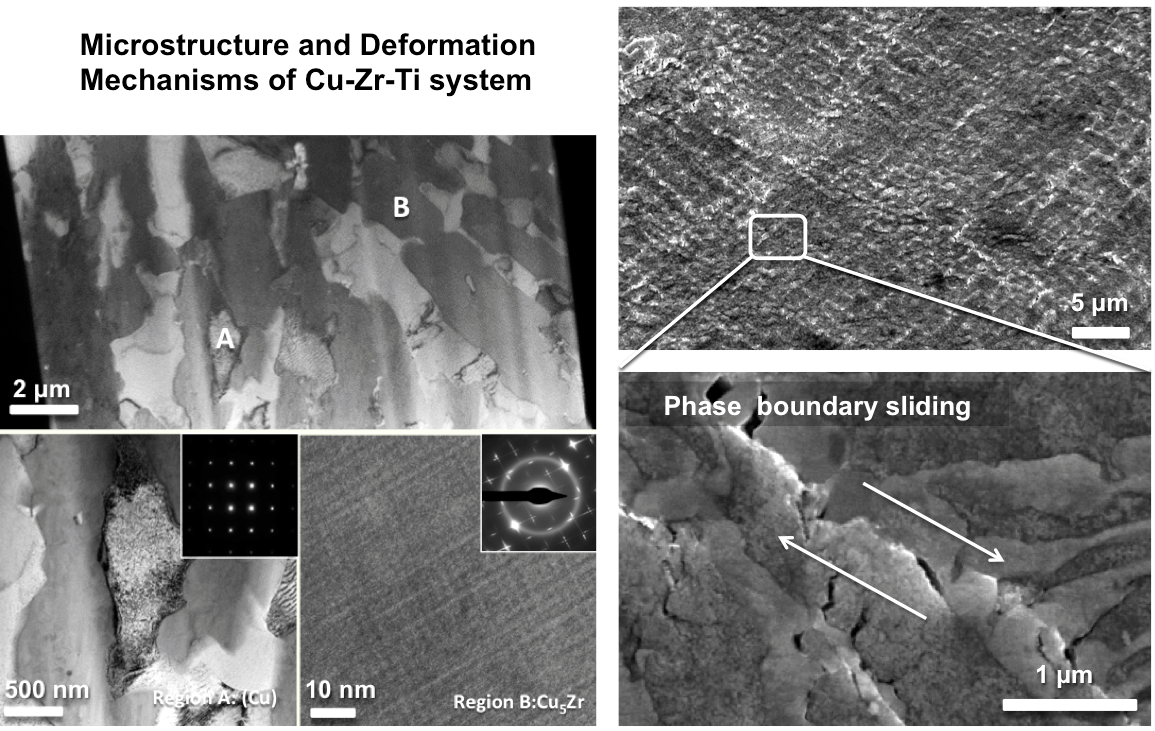

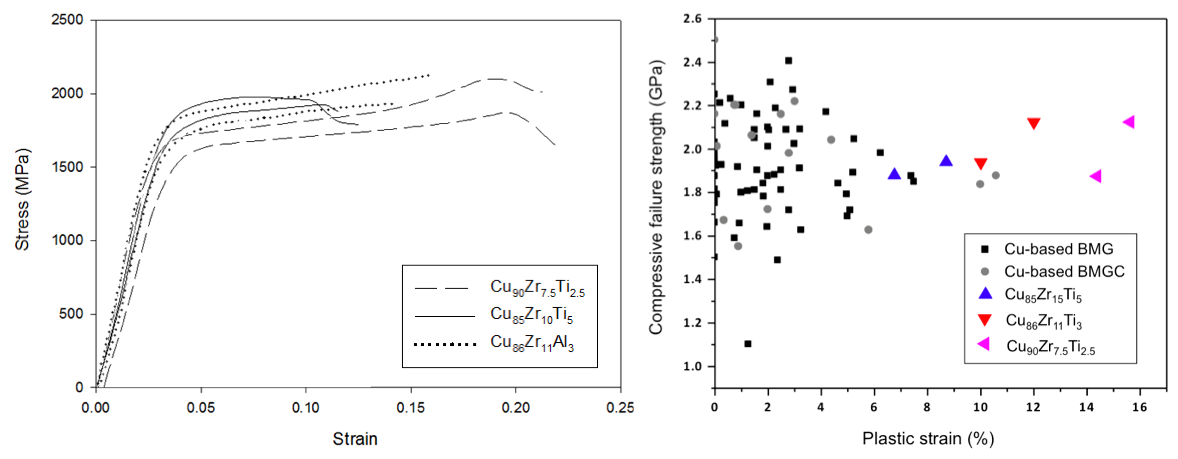

Lee’s research group is developing a new class of metal-intermetallic nanocomposites that possess superior strength, high ductility and excellent high temperature stability as well as the low fabrication price. We use the composition within a narrow eutectic region right next to pure metal, and rapid solidification allows the ultra-fine microstructure to form with the minimal use of expensive secondary element. We believe that our metal-intermetallic nanocomposites would be considered as the alternatives of NC metals and BMGs.

Collaboration Efforts)

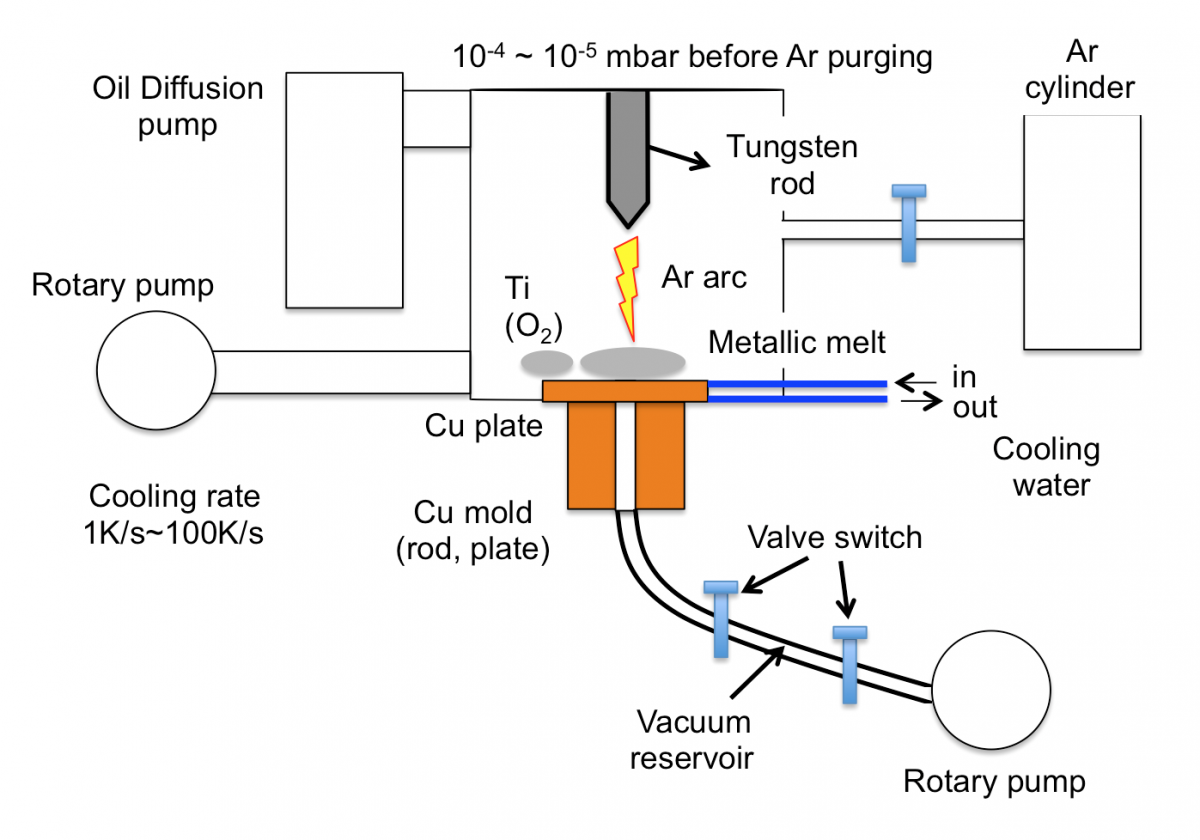

- Arc melting and casting: Dr. Rainer Hebert’s research group at the MSE department of UConn

- Transmission electron microscopy: Dr. Mark Aindow’s research group at the MSE department of UConn

- Advanced computer simulations: Dr. Avinash Dongare’s research group at the MSE department of UConn

Undergraduate student participation)

- Thomas Bissell (MSE, Class 2016), Andrew Jeffrey (MSE, Class 2016), Jackie Lee (CBE, Class 2017)

- Jack Morley, Leopoldo Valencia Jr, Andrew Boucher, Jacob Mount (MSE, Class 2017)

< “Arc melting + Suction Casting” system >

< Superlattice containing Cu-based nanostructure alloys >

<Superior strength and ductility of novel Cu-based metal-intermetallic nanocomposites>

Keith J. Dusoe, Sriram Vijayan, Thomas R. Bissell, Jie Chen, Jack E. Morley, Leopoldo Valencia, Avinash M. Dongare, Mark Aindow & Seok-Woo Lee*, “Strong, ductile and thermally stable Cu-based metal-intermetallic nanocomposites,” Scientific Reports 7 40409 (2017)