(Current Sponsor: UConn and U.S. Army Research Laboratory)

(1) Gold micro-/nano-particles

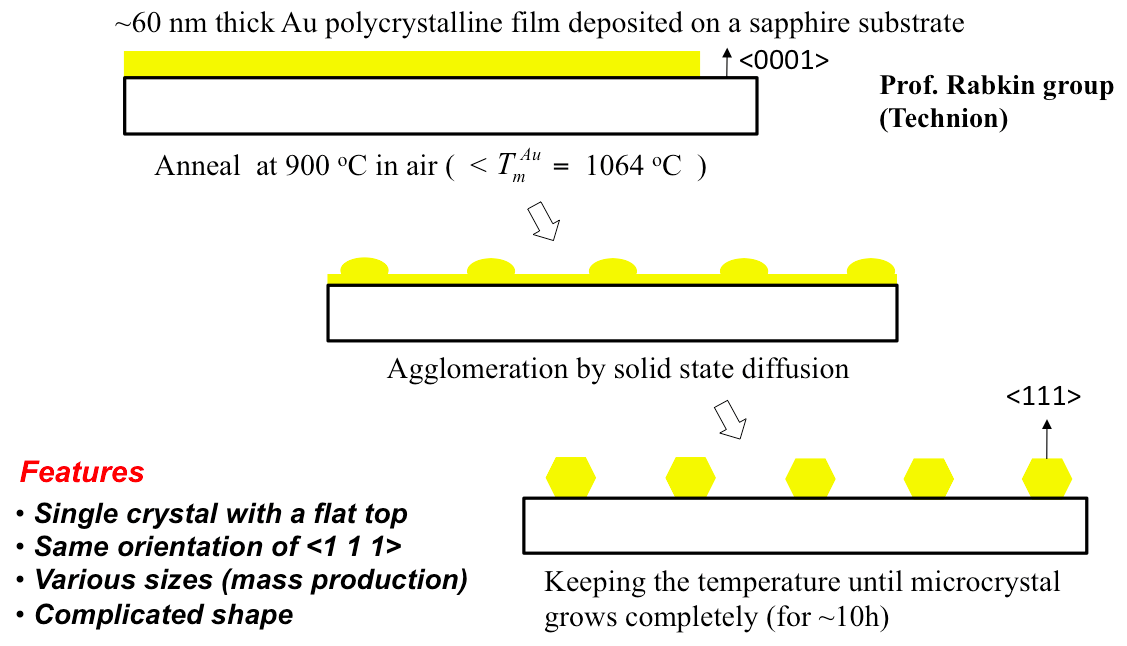

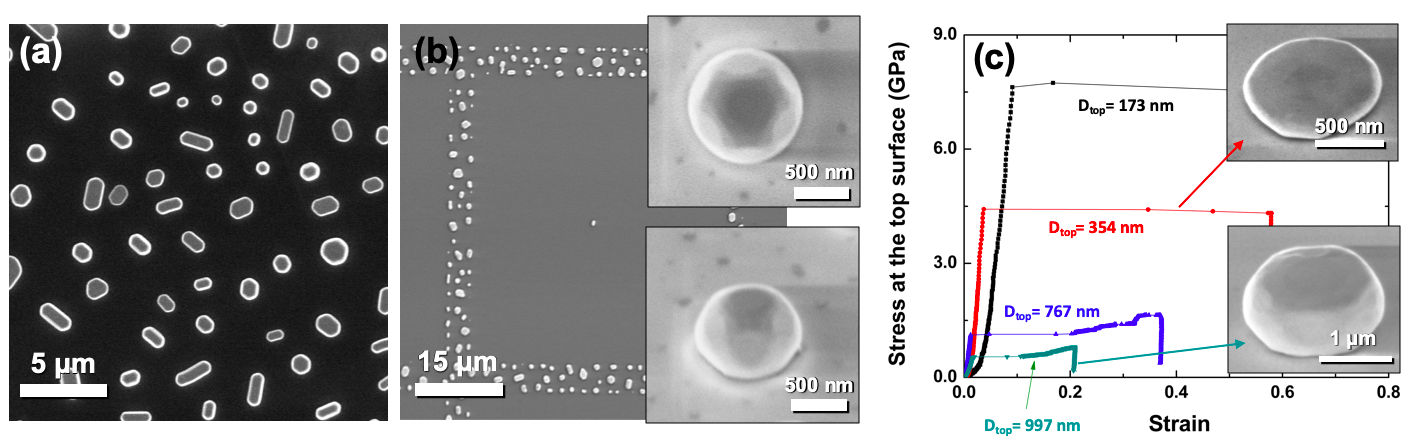

Mechanical properties of dislocation-free material is highly dependent of surface structure because the plastic deformation is controlled by the heterogeneous nucleation of dislocations at the free surface. Thus, the modification of surface structure make a strong impact on mechanical properties of dislocation-free material. Solid state detwetting is a good method to produce a dislocation-free particle on sapphire substrate. Sputter-deposited metallic thin film on sapphire substrate is annealed just below its melting point. Then, solid-state diffusion occurs and micron-sized crystals are formed due to the dewetting condition.

Collaboration Efforts)

- Prof. Eugen Rabkin’s research group at Technion (Israel)

< Solid state detwetting of gold microparticles >

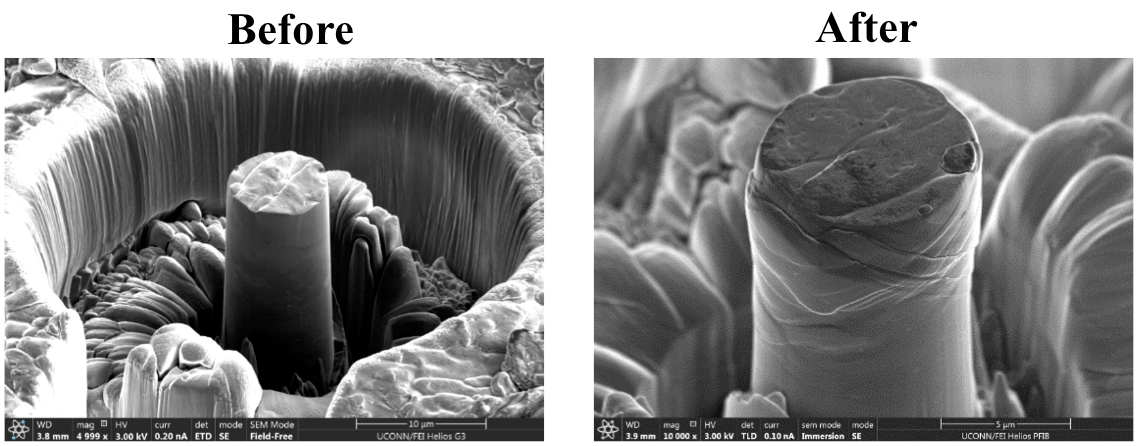

< SEM images of gold microparticles >

(Tyler J. Flanagan, et al., “The effect of defects on strength of gold microparticles,” Scripta Materialia, 171, 83-86 (2019))

Related Publications

- Tyler J. Flanagan, Oleg Kovalenko, Eugen Rabkin, Seok-Woo Lee, “The effect of defects on strength of gold microparticles,” Scripta Materialia, 171, 83-86 (2019) [PDF] [web]

- Roman Kositski, Oleg Kovalenko, Seok-Woo Lee, Julia R. Greer, Eugen Rabkin, Dan Mordehai, “Cross-split of dislocations: an athermal and rapid plasticity mechanism,” Scientific Reports 2 25966 (2016) – [PDF][web].

- Seok-Woo Lee, Dan Mordehai, David J. Srolovitz, William D. Nix, Eugen Rabkin, “Effects of focused-ion beam irradiation and prestraining on the mechanical properties of FCC Au microparticles on a sapphire substrate,” Journal of Materials Research 26 1653-1661 (2011) Invited Feature Paper of the symposium P in the MRS 2010 Fall meeting [PDF][web].

- Dan Mordehai, Seok-Woo Lee, Björn Backes, David J. Srolovitz, William D. Nix, Eugen Rabkin, “Size effect in compression of single-crystal gold microparticles,” Acta Materialia 59 5202-5215 (2011) [PDF][web].

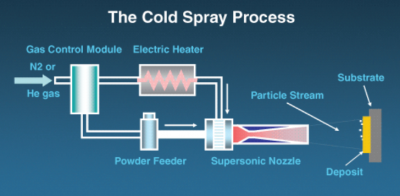

(2) Al microparticles for cold-spray applications (supersonic impact)

The cold spray process utilizes a high pressure gas jet to accelerate metallic particles to supersonic velocities. Upon impact with a surface, these particles will bond to the substrate above the material’s critical velocity. The collision causes extremely severe plastic deformation, which results in non-equilibrium microstructures. Therefore, the mechanical characterization of these impacted particles is of great interest the unusual microstructure leads to unique deformation mechanisms, which is related to the intrinsic mechanical properties of cold sprayed coating.

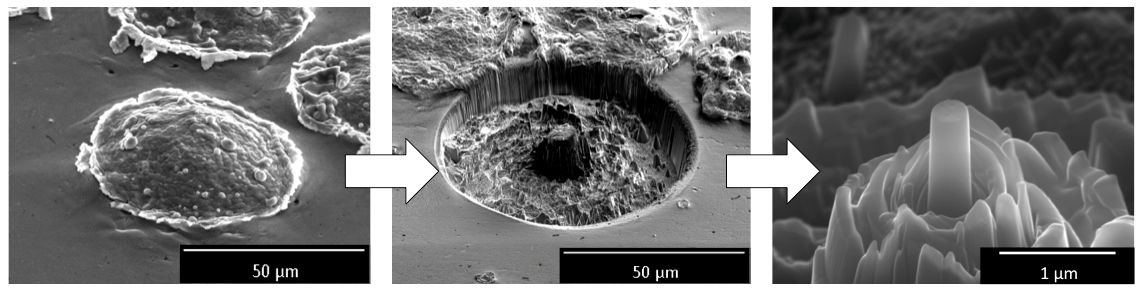

In our work, we study micro-mechanical properties of cold sprayed of Al 6061 powders onto substrates of the same alloy with various velocity (about ~1 km/s). The mechanical properties of these splats are studied by utilizing Ga+ focused ion beam to machine micro-pillars. These pillars are then deformed by micro-compression in situ in SEM using a purpose-built deformation stage.

Collaboration Efforts)

- Prof. Mark Aindow’s research group at UConn

- Prof. Avinash Dongare’s research group at UConn

- Supported by Dr. Victor K. Champagne at U.S. Army Research Laboratory (ARL)

< Micropillar fabrication of cold-sprayed Al particles >

< Micropillar compression >

< Micropillar tension >

(Tyler J. Flanagan, et al., “Mechanical properties of supersonic-impacted Al6061 microparticles,” Scripta Materialia, 171, 52-56 (2019))

Related Publications

- Sumit Suresh, Seok-Woo Lee, Mark Aindow, Harold D Brody, Victor K Champagne, “Mesoscale evolution of jet initiation behavior and microstructure evolution during cold spray single particle impact,” Acta Materialia – 182, 197-206 (2020) [PDF] [web]

- Tyler J. Flanagan, Benjamin Bedard, Alex Ernst, Avinash M. Dongare, Seok-Woo Lee, Harold D. Brody, Victor K. Champagne Jr, Mark Aindow, “Mechanical properties of supersonic-impacted Al6061 microparticles,” Scripta Materialia, 171, 52-56 (2019) [PDF] [web].

- Benjamin Bedard, Alex Ernst, Tyler J. Flanagan, Avinash M. Dongare, Seok-Woo Lee, Harold D. Brody, Victor K. Champagne Jr, Mark Aindow, “Microstructure and micromechanical response in gals-atomized Al6061 alloy powder and cold-sprayed splats,” Journal of Thermal Spray Technology 27 1563-1578 (2018) [PDF] [web]

- Sumit Suresh, Seok-Woo Lee, Mark Aindow, Harold Brody, Victor R. Champagne, Avinash M. Dongare, “Unraveling the mesoscale evolution of microstructure during supersonic in aluminum powder particles,” Scientific Report 8, 10075 (2018) [PDF][web]